Introduction to Forced Convection Roasting

Our process of patented Roasting is different and world unique. This uniqueness was tested during the patenting process, based on the ease of the application as well as the low running cost of this precision process

The following advantages to use Roastech’s technology can be listed:

- The machines can run 24 hours a day without intensive supervision like other traditional processes

- The temperature can be manipulated by the operator, thus allowing warmer and colder roasting processes

- The exact speed of material through the roaster can be managed with an optional variable speed drive, therefore allowing faster and slower roasting processes

What application is suitable for the Roastech range of Roasters?

- Soybeans, Roasted&Rolled Grains&Cereals, Oats, Barley.

- Shelled Ground Nuts, Other forms of peanuts.

- Roasting and Blanching of Ground Nuts

- Roasting and flaking of Maize, Oats, Barley

- Roasting of Nuts and seeds

- Roasting of spices such as Coriander

- Other: Sterilizing of seeds (Aflatoxins are odorless, tasteless and have no color, and are difficult to detect if not sterilized.

- Other: Heating of sunflower seeds for the cold press industry

Nutriroast Reviews

One of PPBs most important ingredients in producing RUTFs is peanuts. Which in turn requires 100s of metric tons of raw peanuts a year to produce.

Essential to this production is our peanut processing line that takes raw peanuts and prepares them for production use in our RUTFs. The line starts with sizing, de-stoning, blanching, white roasting at 45 Celsius, followed by optical sorting and manual sorting where they are stored in metered out buckets until we run the peanuts through the final roaster.

Here at the final roaster is one of our most important kill steps, where any existing bacteria or organic matter is eliminated while the peanuts roast at 165-175 Celsius. After this step they are ready for production use in our RUTFs. To achieve this large scale production on our peanut processing line we heavily rely on the technological expertise and durability of our two most important pieces of Roastech equipment 1. White roaster 2. Final roaster. Over the last 7 years our Roastech equipment has been very consistent in operating and requires little maintenance. Without our Roastech equipment PPB would not be able to achieve our goals of feeding hundreds of thousands of malnourished children throughout Africa. PPB highly recommends Roastech - high performing and high quality machinery, with friendly customer service and a solid reputation built on years of reliable success. We have roasting lines at PPB Ghana and PPB Malawi.

My name is Randy Gubersky, President of Gubersky Gluten-free Organics.

We farm in the central, Alberta, Canada area.

A number of years ago, I chose to add "value added oatmeal", to our gluten-free, organic oat crops. I was looking for a complete roasting system that would be simple and efficient to operate, but have the ability to produce a top quality tasting oatmeal product. I found that with the Roastech Roasters.

The patented roasting procedure is done incredibly even, throughout the entire groat seed. The final oatmeal flake produced, is what my customers are looking for. I purchased the R300E Dairy Grade Stainless Steel roaster system and understood that it will run most efficiently 24 hours per day ( that is a lot of production that can be done).

One concern I've always had referencing new equipment purchases was customer service from the manufacturer. Roastech has been outstanding with any questions I ever have had. Bianca, with Roastech has been pivotal in supplying answers to whatever questions I needed answers for. That is a very important avenue to have confidence with, when you are trying a new equipment system, and Roastech has that taken care of very well.

The Roasting Process

Our process of patented Roasting is different and World unique. This uniqueness was tested during the patenting process

Application in Human Foods

Enhances the natural flavor of nuts and grains roasted because of the healthy processing technique

Application in Animals Feeds

It’s a good source of protein and fat for poultry. Soybean seed contains a trypsin inhibitor that can severely interfere with digestion in a bird's gut

Forced Convection Roasters

Turn Key Solutions

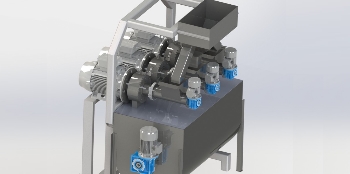

Nut Butter Equipment

Oats Treatment

Product Cleaning

Cooling Units

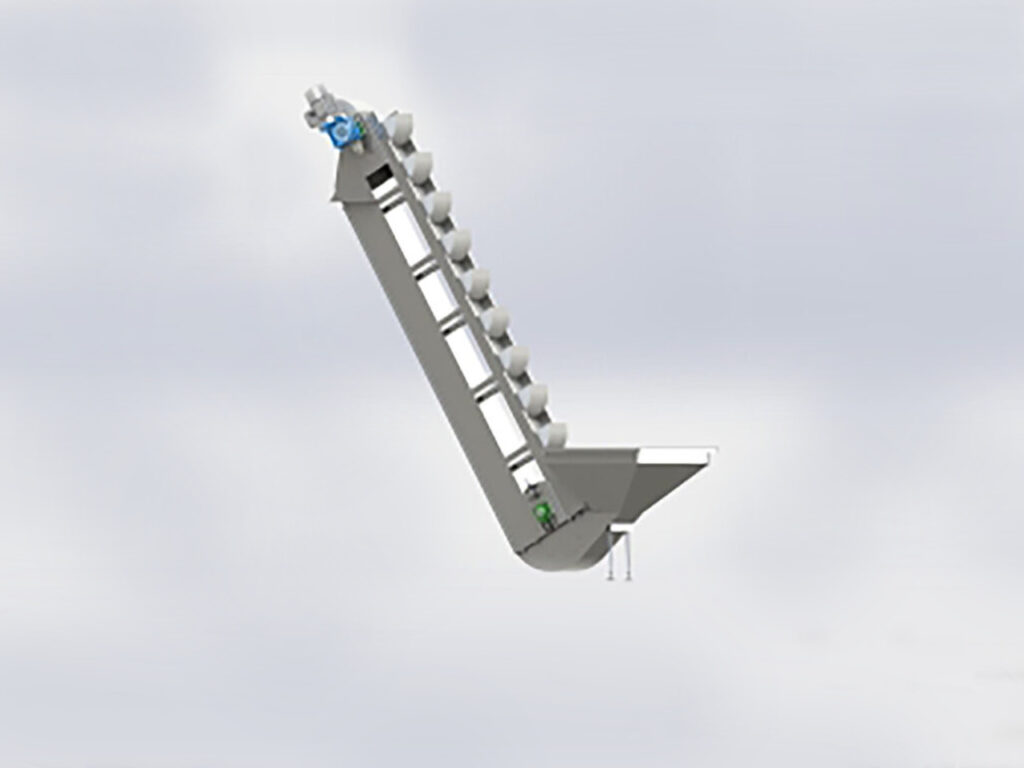

Product Conveying

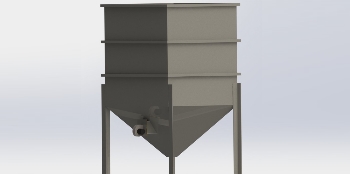

Storage Bins

Welcome to NutriRoast Breakthrough Roasting System Solutions

You have come to the right place! We are so excited to meet and exceed your roasting needs! Roastech Roasters use Forced Convection of Hot Air Technology. This means evenly distributed heat. Even heat distribution means optimized Nutrition and Flavor. Nutrition is the Key Foundation of Health.

About Us

We are dedicated to providing quality Roasting System Solutions that's safe and beneficial to your health that: It matters how you roast it.

- Don’t burn it

- Don’t overcook it

- Don’t undercook it

- Don’t fry it

- Don’t radiate it

- Don’t toxify it

Just roast it gently and evenly with Forced Convection of Hot Air. We hope will choose The Roastech Advantage for your business today.